General information

-

Company nameCeit

-

AddressPaseo Manuel Lardizabal 15, 20018 Donostia-San Sebastián

-

Turnover25.50 million EUR in year 2023

-

Employees280 in year 2023

-

SMENO

-

Contact Info:

-

Phone943212800

-

Emailinfoceit@ceit.es

Activity and Skills

Ceit is a nonprofit private research center with the mission to serve the industrial sector, carrying out projects of applied research and technological development. Ceit is a multidisciplinary center, whose work is oriented to different sectors: railway, aeronautical, automotive, health, manufacturing, energy, environment and ICT.

Ceit's capabilities and interest with regard to large scientific facilities are:

- Development of materials and components for extreme environments: graphitic materials, self-passivating W alloys, ODS Steels, EUROFER, CuCrZr, porous silicon carbon with tailored porosity.

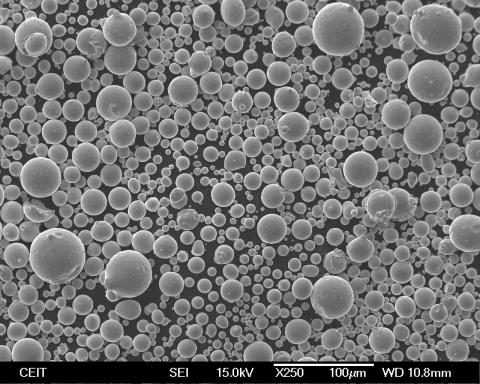

- Design, production and processing of powders. Equipment with metal/gas atomizer to produce tailored metallic powders for Additive Manufacturing or (Near) Net Shape technologies. From 1 kg up to 250 kg of powder with composition within ITER/EUROfusion specifications: ODS Steels, EUROFER, CuCrZr, Cu-OHF.

- HIP. Consolidation of ceramic and metallic powders encapsulated in cannisters, removal of residual porosity in castings or components obtained by Additive Manufacturing.

- Additive Manufacturing: PBF-LB (powder bed fusion laser beam), BJ (Binder Jetting), wire and powder DED-L (laser beam directed energy deposition).

- High precision Femtosecond Laser surface processing.

- Solid state diffusion bonding of Cu, CuCrZr, AISI 316L, EUROFER, ODS steels and tungsten.

- Failure analysis. Identification of failure mechanism (mechanical and thermomechanical fatigue, fractography analysis...). Advanced techniques for residual stresses measurement.

- Electronic and magnetic NDT for microstructural characterization and identification of defects and cracks.

- Thermal Physical, mechanical and microstructural characterization (SEM, TEM, AFM).

-Remote handling: haptic devices (mechatronics background), control engineering (teleoperation, mobile cobots, low latency communication systems like 5G), own XR technology for remote asistance, 2D and 3D vision for metrology, quality inspection and perception.

-AI applied technologies: machine learning, generative AI, NeRF, Deep Learning...

-Cybersecurity.