General information

-

Hosting OrganisationAIMEN TECHNOLOGY CENTRE

-

AddressPolígono Industrial de Cataboi SUR-PPI-2 (Sector 2) Parcela 3 36418 O Porriño (Pontevedra)

-

Contact Info:

-

Phone

-

Emailaimen@aimen.es

Description

AIMEN Technology Centre, founded in 1967, is a multi-sector Innovation and Technology Centre that develops R&D&i activities and provides technological services to the industry in the fields of materials, advanced manufacturing processes, digitization and sustainability.

58 years in the service of industry, combined with our technical experts’ high levels of specialisation and the unique nature and excellence of our facilities, endorse the quality of our multidisciplinary and multi-sectoral technological offer. We carry out our own research, and also partner with companies on R&D projects aimed at developing new technologies and incorporating technological improvements into their products and/or processes, including the development of prototypes and demonstrators. Aligned with a common purpose: to maximise business an dindustrial performance.

Summary of Research Services

Our specialization areas in R&D are: Laser Systems and Applications, Advanced Composites Technology, Smart Systems and Smart Manufacturing and Enviromental Tecnologies. Our specialization areas in Industrial Services are: Simulation and Engineering, Advanced Manufacturing, Smart Industry and Materials Lab. Our laboratories are backed by many official accreditations and recognitions that guarantee our impartiality and technological capabilities.

Technology Capabilities

- High Performance Materials.

- Flexible Production Processes and Systems.

- Robotics and Automation.

- Micro and High Precision Manufacturing.

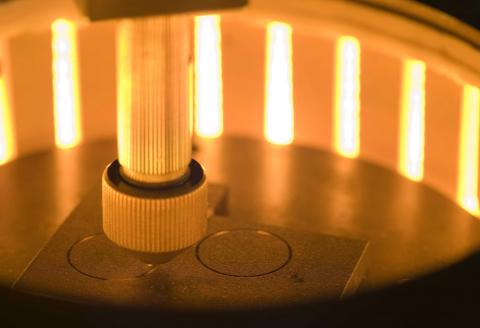

- Laser Based Manufacturing.

- Environmental Technology.

- Industrialization.

Main equipment or Facilities

We have over 10,000 m2 of scientific and technological infrastructure, equipped with state-of-the-art equipment, unique laboratories, and pilot plants to offer a technological offering with the highest guarantees.