General information

-

Company nameSGENIA INDUSTRIAL

-

AddressAvda Zumalakarregi 48. 46008 Bilbao

-

Turnover0.90 million EUR in year 2023

-

Employees9 in year 2023

-

SMEYES

-

Contact Info:

-

Phone916306388

-

Emailsgenia@sgenia.com

Activity and Skills

SGENIA INDUSTRIAL is a company specialized in the engineering and manufacturing of products and components in different activity areas like Energy, Aerospace and Defence and Industrial. In all these sectors different fields are worked. SGENIA INDUSTRIAL develops, promotes and executes industrial “based-on-technology” projects and works for large European scientific facilities (ITER, ESA,…) and is also involved in international partnerships together with the strongest European research centers and universities

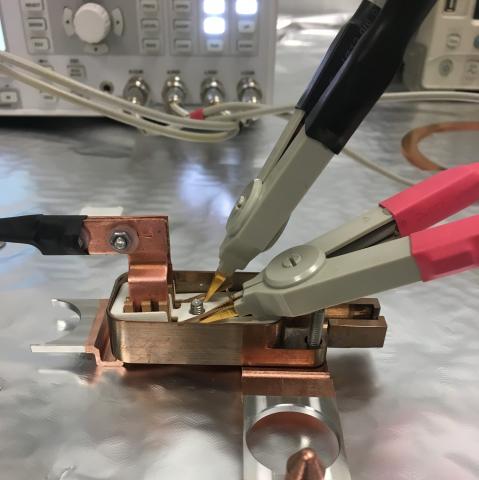

SGENIA INDUSTRIAL designs, manufactures and tests robotic equipment. Sgenia has capability of full mechanical and electronic design, as well as of development and integration of embedded sensors on robots. Extreme conditions robots have been manufactured for nuclear and military environment. Sgenia develops the control systems and our software department has experience in developing rich graphical interfaces, high quality visualization and augmented reality to assist robot monitorization.

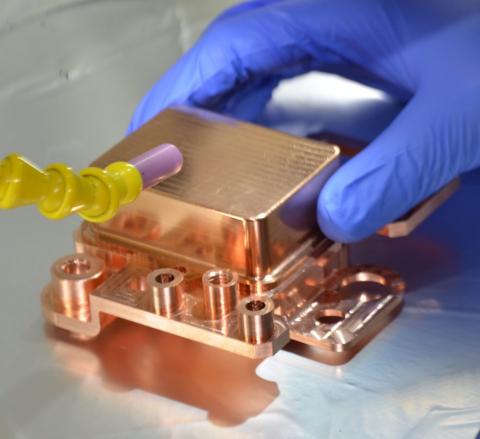

Engineering Capabilities: 1) Thermal, Mechanical and Electrical design of components, devices and equipment, 2) Engineering for ultra and high vacuum, cryogenic and special gasses installation, 3) Pressure equipment services: modelling, design and manufacturing

Manufacturing capabilities: 1) High accuracy machining of metallic and ceramics components, 2) Specials alloys and materials (Inconel, tungsten, ceramics,...), 3) TIG, Brazing, EBW and Laser welding for UHV conditions, 4) Vacuum services: outgassing test and leakage detection in UHV conditions

Advanced software development: 1) Advanced algorithms (machine learning, tomography algorithms,...), 2) Sensor design and integration