General information

-

Company nameIDRESA

-

AddressPCTCAN, Isabel Torres 11, Edificio 3000, M 7

-

Turnover0.61 million EUR in year 2024

-

Employees4 in year 2024

-

SMEYES

-

Contact Info:

-

Phone+34689107730

-

Emaileng@idresa.es

Activity and Skills

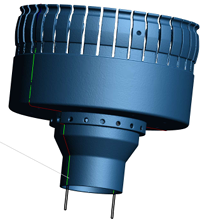

IDRESA SERVICES specializes in advanced engineering, manufacturing, and integration for high-value sectors such as science, space, nuclear, and defense. As part of Grupo Resa, we combine technical expertise, cutting-edge technology, and an innovative approach to deliver tailored solutions for highly complex projects.

Our Capabilities

🔹 State-of-the-art engineering – From conceptual design to turnkey solutions.

🔹 Precision manufacturing – Components for ultra-high vacuum, cryogenics, and radiofrequency.

🔹 Integration & testing – Ensuring maximum performance and reliability.

🔹 Specialized outsourcing services – Providing talent and resources for high-tech projects.

Our expertise lies in radiofrequency, microwaves, cryogenics, ultra-high vacuum, and precision mechanics, allowing us to develop innovative solutions for the most demanding industries.

We invest in R&D and have established a dedicated integration laboratory to ensure quality and efficiency at every stage of the process.