General information

-

Company nameESTEYCO SA

-

AddressAvenida de Burgos, 12B-Bajo I 28036 Madrid

-

Turnover28.00 million EUR in year 2023

-

Employees240 in year 2023

-

SMEYES

-

Contact Info:

-

Phone+34913597878

-

Emailmechanics@esteyco.com

Activity and Skills

Esteyco is an independent engineering and consulting firm with 250 employees and more than 50 years of experience all over the world.

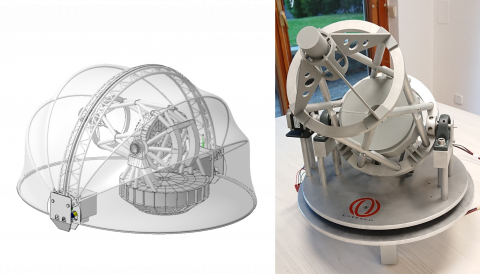

Activities in Big Science cover the design, analysis, manufacturing, assembly, testing and commissioning of complex structures and mechanical systems. This is implemented through either an integrated approach, spanning the whole development cycle, or specialized consultancy services at different stages of the project.

Esteyco’s focus is on non-conventional developments with stringent thermal and/or mechanical constraints that require going beyond what is common practice in structural and mechanical engineering. In-depth knowledge of engineering principles and state-of-the-art capabilities are applied by Esteyco to ensure compliance with requirements. Main Esteyco assets include:

i) Large experience in the design and manufacturing of complex and one-of-a-kind mechanical systems.

ii) Advanced analysis capabilities and sound engineering judgement in an extremely wide range of disciplines.

iii) Familiarity with main design and construction codes.

iv) Combined and strongly coupled civil-mechanical engineering approach, essential for those developments involving large components and complex interfaces.

v) Expertise in instrumentation and state-of-the-art developments in the engineering oriented interpretation of experimental data.

vi) Mechatronics.