General information

-

Company nameENUSA Industrias Avanzadas S.A., S.M.E.

-

AddressC/ Santiago Rusiñol, 12. 28040 Madrid (SPAIN)

-

Turnover339.00 million EUR in year 2024

-

Employees585 in year 2024

-

SMENO

-

Contact Info:

-

Phone+34913474200

-

Emailcomunicacion@enusa.es

Activity and Skills

(1) Nuclear business. Currently the company focuses its nuclear business on the first part of the fuel cycle that it markets both nationally and internationally. Our business areas include uranium and supply, design and engineering, manufacturing, services at the plant, dismantling and radioactive waste management.

a. Uranium Supply: we manage the enriched uranium supply to the electric companies that own the Spanish nuclear power plants. We carry out the procurement of supplies with major global suppliers and maintain contracts with main global suppliers of uranium concentrates, conversion services, and enrichment services. Our portfolio of suppliers allows us to maintain a policy of diversification of sources, flexibility, security of supply and very demanding prices. We also carry out the logistics management.

b. Design and Engineering: from conceptual development and introduction to storage and transport. We have the latest technological advances through transfer agreements with our partners and licensors Westinghouse and General Electric (GE). This allows us to cover the design, manufacture and supply of fuel to domestic and foreign nuclear power plants, as well as all engineering services related to the management and optimization of fuel use in the reactor. The fuel engineering developed at ENUSA covers all technical aspects of the nuclear fuel lifetime:

• development and introduction of new products and design methodologies;

• engineering of reloads and safety analyses;

• definition of the product to be manufactured and manufacturing support;

• monitoring fuel behaviour in the core;

• analysis of operational experience and subsequent feedback of the design and its tools;

• characterisation and analysis for the classification of irradiated fuel for dry storage and transport.

In ENUSA, engineering is supported by powerful R&D&I, cooperating with Spanish universities through collaboration projects or participation in training activities, and in the promotion of and/or participation in national and international projects on key technical aspects of fuel.

c. Manufacturing: we manufacture for Spanish and European nuclear power plants, integrating the most innovative technology and the latest advances on the market. The manufacture of fuel assemblies is divided into two processes: ceramic process and mechanical process. The fuel assemblies are manufactured in our factory in Juzbado (Salamanca).

• PWR: Pressurised water reactors, under license from Westinghouse

• BWR: Boiling Water Reactors, General Electric

• VVER: Pressurised water reactors, in collaboration with Westinghouse

We develop the necessary equipment and processes in-house to manufacture the different products with the highest safety, quality and efficiency. The development and optimisation of the inspection and manufacturing equipment we use, places ENUSA in a privileged position to supply highly advanced equipment for nuclear fuel factories, a line of business in which we have been working for several years, either individually or in collaboration with other partners such as Tecnatom.

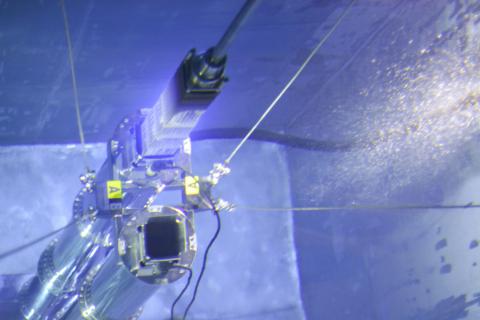

d. Services at the Plant: We coordinate handling, inspection and repair campaigns in line with refuelling programmes, performing fresh fuel reception and irradiated fuel handling services, supervising the process during refuelling outages. Our performances are:

• Handling of fresh and irradiated fuel.

• Leaking fuel detection by sipping and ultrasonic inspections.

• Visual inspection and control, fuel repair.

• Ultrasonic cleaning.

• Fuel inspection and characterisation.

• Systems for the detection and removal of foreign objects from fuel and other accessible areas.

• Lighting systems and core loading/unloading control.

• Ultrasonic fuel cleaning to remove crude oil deposits from the surface of the rods.

As a result of all this experience, at ENUSA we are also prepared to carry out the necessary activities for the management of irradiated fuel.

e. Dismantling and Radioactive Waste Management: We work in nuclear facility decommissioning and radioactive waste management on solutions that allow us to automate radiological characterization of walls, land and waste, with the consequent reduction of doses for workers, optimization of execution times and reduction of the volume of waste generated during the dismantling of nuclear power plants. From an operational point of view, we are aware of the importance of minimizing the volume of waste. In this line, we are making a great effort in the technological development of projects, installations and solutions for the decontamination of waste and surfaces, the reduction of the volume occupied by the waste generated, and the reduction of the volume of waste generated and the declassification of materials for their revaluation or storage as conventional waste. The technological component and innovation, linked to the qualification of personnel and process automation, are a fundamental part of the work we do, which is why ENUSA is building an Equipment Technology and Maintenance Centre as an operations centre for the development of these activities.

• Development of equipment, robotization of activities and qualification of personnel.

• Radiological characterization of soils.

• Radiological characterization and declassification of walls.

We also carry out radiological studies:

• Radiological characterization of sites.

• Radon exposure study in accordance with the provisions of Royal Decree 1439/2010, of 5 November, amending the Regulation on health protection against ionizing radiation.

• Environmental radiological impact assessment of NORM industries.

• Design and implementation of environmental radiological monitoring programs.

• Conducting physic-chemical and radiological tests on water, soil, sediment, biota and air filter samples.

• External personal and environmental dosimetry services.

(2) Logistics business: ETSA Global Logistics, S.A.U., S.M.E., a subsidiary of the ENUSA Group, is a global multimodal transport operator (land, sea and air) of dangerous goods of all kinds, specializing in radioactive and nuclear goods. It also transports chemical products, biofuels, hazardous and non-hazardous waste.

(3) Environmental business: it focuses on services for environmental conservation and energy efficiency. Through our subsidiary EMGRISA we carry out the treatment and management of all types of waste, characterisation and treatment of contaminated soil and water, environmental engineering and consultancy and radiological studies. EMGRISA collects, transports and manages hazardous and non-hazardous industrial waste, prioritising reuse and recovery actions.