General information

-

Company nameDem Barcelona

-

AddressC/Puigmal, 94-96 , Polígon Industrial Sant Isidre, E-08272, Sant Fruitós de Bages (BARCELONA), Spain

-

Turnover9.50 million EUR in year 2023

-

Employees86 in year 2023

-

SMEYES

-

Contact Info:

-

Phone+34938773181

-

Emaildem@dem-barcelona.com

Activity and Skills

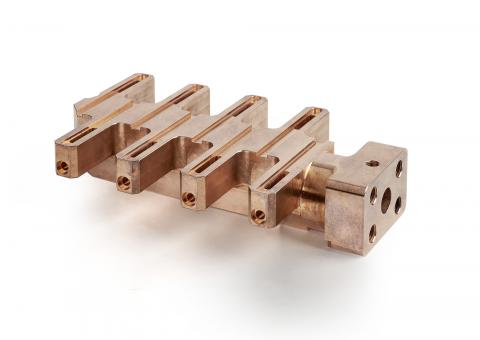

DEM Barcelona is a company specialized in High Precision Machining Processes for Copper, Aluminum and Stainless Steel customized projects. Our 30 years of experience give us a wide know-how in copper machining, bending and deep drilling. From 2017, DEM has been involved as a subcontractor in different Big Science projects for ITER, and also CERN or ALBA. DEM also produces items for other sectors such as automotive, railway, particle accelerators, medical, aerospace, etc. Our main markets are Germany, Spain, France and US.

Dem has 2 production plants, one in Barcelona, and another in Mexico. Dem Barcelona offers our services thanks to our facilities of 3000 m2 with more than 30 machines: Machining Centers and Turning CNC machines, 5 axis CNC for parts up to 3 meters long, deep drilling machines for parts up to 2 meters long, bending machines...

Dem deals directly with Copper Manufacturers, and we have around 200Tn Stock of Copper in different alloys. Traceability is essential for any single project, and we take care of all special specs requested for any kind of copper alloy. We do also offer project management follow up for special copper short series productions.

Our Project Management Engineering Team follows up every single project from beginning to delivery, to achieve the demanding tolerances, technical requirements and material alloy specifications of our customers.

Our Quality Policy in DEM is a Must, with a strict production. Verification processes are made by a wide range of equipment, including Three-Dimensional Control Machines (2 stables and 3 portables, one of them to verify pieces up to 3 mts long), a Roughness Meter device, portable durometers, ultrasound machine, etc.

Our expertise in Dem allows us to be your production partner for your customized copper needs.