General information

-

Company nameCentro Tecnológico CTC

-

AddressCalle Isabel Torres 1, PCTCAN

-

Turnover1.40 million EUR in year 2023

-

Employees36 in year 2023

-

SMEYES

-

Contact Info:

-

Phone+34942766976

-

Emailinfo@centrotecnologicoctc.com

Activity and Skills

CTC Technological Centre was founded in the year 2000 as a private non-profit-making foundation. It has been recognized as a Technological Centre by the Ministry since 2008 under entry nº 79. Ever since then it has been the only technological center in Cantabria region (Spain) to have been awarded this distinction, which recognizes non-profit-making entities with the major objective of improving the competitiveness of companies by means of the generation of technological knowledge and which carry out Industrial R&D activities and develop their application.

The mission of the Technological Centre CTC is to enhance companies by means of the application of Science and Technology, designing practical advanced solutions for industry. CTC intends to establish a close relationship with companies to develop innovative processes of technological transfer to increase the competitiveness of the industrial fabrication and facilitate the companies’ access to international markets.

CTC is a multisectorial institution and includes three knoledge areas where it developes its R&I projects: Advanced Materials & Nanomaterials, Industry&Energy and Navigation&Robotics.

The areas of specialization of interest for Large Scientific Infrastructures include:

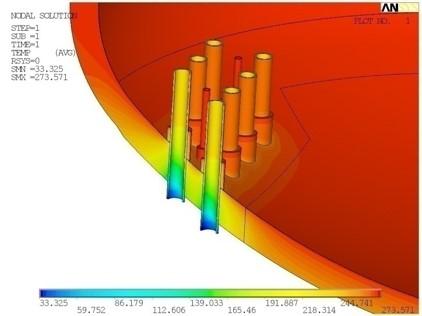

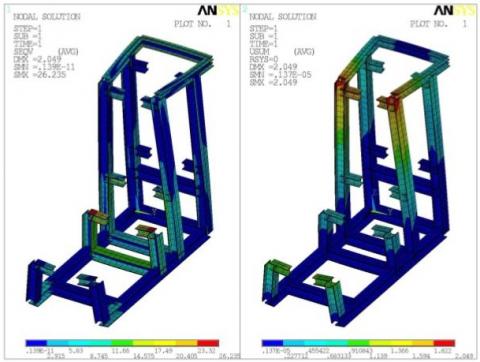

- Engineering and Numerical Simulation. FEM&CFD Structural, thermal and fluid-dynamics calculation.

- Coatings and material/electronics shielding.

- IA aplications on time series and prediction systems.