General information

-

Company nameIDONIAL TECHNOLOGY CENTRE

-

AddressParque Científico Tecnológico de Gijón, Zona INTRA. Avda. Jardín Botánico, 1345 33203 Gijón, Asturias

-

Turnover10.05 million EUR in year 2024

-

Employees161 in year 2024

-

SMENO

-

Contact Info:

-

Phone+34985129120

-

Emailinfo@idonial.com

Activity and Skills

IDONIAL is a Spanish private technological centre, with more than 30 years of experience. The center is multisectorial and carries our R&D&I activities from the following areas: Materials (metals, ceramics, plastics), Advanced Manufacturing (Additive Manufacturing, Welding), Digital Industry (Industry 4.0) and Engineering (Numerical Simulation, Mechanical and Electronic Engineering). In addition, relevant Technological Services backed by official accreditations are available.

The areas of specialization of interest for Large Scientific Infrastructures include:

- Steels and Metallic Alloys. Development, manufacturing routes and characterization to application. The activities performed deal with extending service life, optimising in-use behaviour, improving mechanical, wear or corrosion resistance, increasing their formability and weldability, new materials selection and application. Specialisation in fatigue & fracture mechanics studies.

- Welding Technologies. Weldability studies, selection of the optimal welding parameters, design & validation of manufacturing technical instructions, manufacturing of special welded mockups and special NDT calibration blocks with advanced welding processes, global and conceptual manufacturing plans, as well as inspection plans. Wide range of techniques including robotic, FSW and laser hybrid welding.

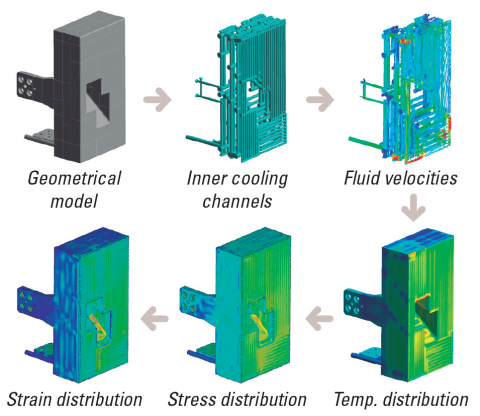

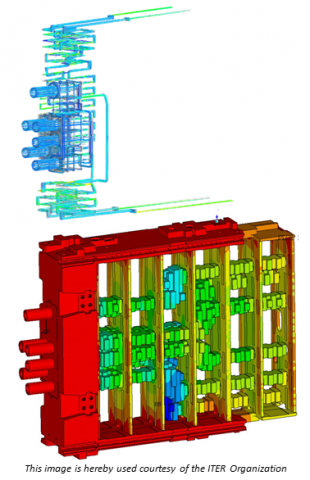

- Engineering and Numerical Simulation. Structural, thermal and fluid-dynamics analyses by FEM&CFD; coupled analyses: thermo-hydraulic, thermo-mechanical. Welding process simulation, distortion prediction, selection of the optimal welding sequence. Large experience with different design codes (RCC-MR, RCC-MRx, ASME, etc), welded structures and complex settings.