General information

-

Company nameVAC-TRON S.A.

-

AddressJuan de la Cierva 6, Nav. G-H, 08420 Canovelles, Spain

-

Turnover2.90 million EUR in year 2024

-

Employees20 in year 2024

-

SMEYES

-

Contact Info:

-

Phone34 938494612

-

Emailfranc.moreno@vac-tron.es

Activity and Skills

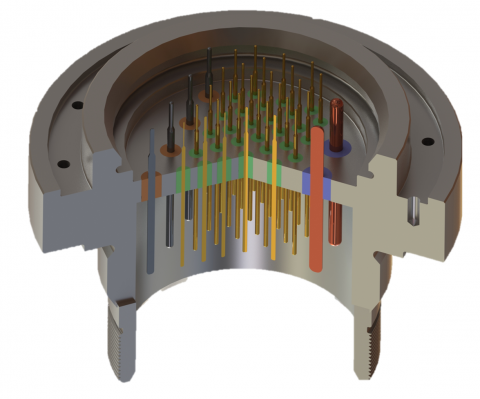

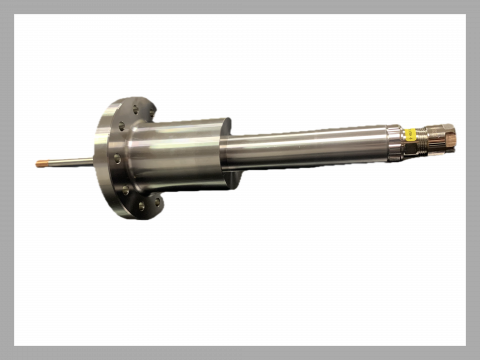

VAC-TRON, S.A. started its activity 40 years ago and is specialized in developing hermetic interconnections to pass electrical signals between two hostile atmospheres. Our core technology is to fuse glass to have a hermetic seal between the electrical conductor pin and the external shell or bulkhead. This is accomplished using the technology of Glass to Metal Seals (GTMS) to produce high-quality hermetic components.

This tecnology gives an extra of performace to our connectors:

- Temperature: -195ºC to 300ºC

- Pressure: up to 2.500 bar

- Hermeticity: <2,69·10-10Pa·m3/s

- Dielectric Strength: 500 V -6.000 V DC

- Electrical Resistivity: >1.000MΩ

At VAC-TRON we try to understand what really needs our customer in order to offer the best solution, manufacturing bespoke Glass to Metal Seals components for a wide range of areas.

Our multidisciplinary team guarantees the needs of our customers.

We have a presence in many sectors as aeronautic, aerospace, automobile, gas industry, medical, military, nuclear and petroleum industry, railroad and telecommunication. We manufacture feedthroughs, relays bases, connectors, sensors and microsensor, bases and lids for filters and oscillators and pyrotechnic igniter bases. To guarantee customer requirements our Quality System is based on the requirements of EN 9100, ISO 9001 and ISO 14001.

Since 2025, we have a clean white room ISO 7 for Ultra High Vacuum projects.

Our facilities include presses and a furnace to produce glass preforms, presses for the stamping of metal components, continuous belt and vacuum furnaces to produce GTMS components, and an area of surface treatments including nickel, tin and gold plating.