AWGE Technologies, S.L.

Imagen

1

Imagen

2

Imagen

3

Imagen

4

Pic legend 1: HARMONI Test cryostat

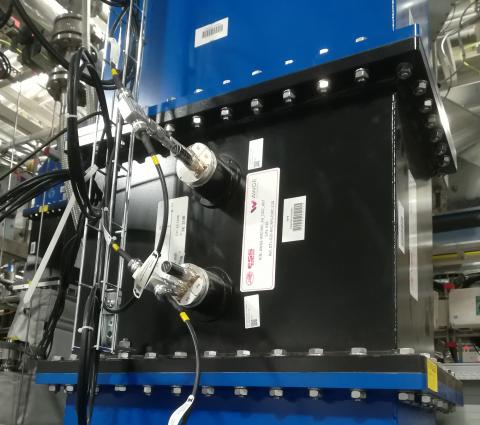

Pic legend 2: Dual Directional Coupler

Pic legend 3: ESS Shaft rotatory unit

Pic legend 4: Phase shifter

General information

-

Company nameAWGE Technologies, S.L.

-

AddressAvda. De los Castros s/n. CDTUC Fase A, P-209, Santander

-

Turnover0.67 million EUR in year 2024

-

Employees7 in year 2024

-

SMEYES

-

Contact Info:

-

Phone+34942136719

-

Emailinfo@awge.es

Activity and Skills

AWGE Technologies is a technological engineering company that concentrates its activities and skills in two main areas. On the one hand Ultra high Vacuum and Cryogenics mixed with mechanics and on the other Radiofrequency and Microwaves for Large Research Infrastructures, institutions and private corporations. In both areas AWGE Technologies carries out projects involving design, manufacturing, production and verification.

Our skills includes provision of innovative solutions on engineering design, manufacture, verification and testing in the fields of particle accelerators, astrophysics, space, defence, industry and health sectors.

Contracts for Big Science facilities

[ALBA]

Control Unit Interface for Spoke Cryomodules Supply (Design and manufacture) of a radio frequency cavity

(2023 - 2024)

Design, manufacture and test for a test cavity for power couplers of the 500 MHz cavities.

The test cavity is basically a pillbox-type cavity where two power couplers are placed 120° apart (for transmission measurements). The goal is to test up to 160 kW of continuous wave (CW) at 500 MHz.

The cavity has an approximate diameter of 475 mm (for resonance of the TM010 mode at 500 MHz) and a length of 250 mm (does not affect the resonant frequency).

[ESS]

Control Unit Interface for Spoke Cryomodules

(2023 - 2023)

Assembly of 1+14 19" and 4UA boxes, with screen-printed front panel and rear panels with machining for connectors (AC, Ethernet, motor, interlock, 4 temperature sensors). DIN rail for mounting power supplies, terminals, fuses, relays and Beckhoff EtherCA T motor control modules (Placement of the modules on the DIN rail; Placement of connectors in panels).

Wiring of 1+14 19" and 4UA boxes, with screen-printed front panel and rear panels with machining for connectors (AC, Ethernet, motor, interlock, 4 temperature sensors). Manufacture and installation of wiring harnesses with crimped socket ferrules and crimped/soldered connectors, cables will have a non-flame spreading and low smoke emission insulating cover (LSZH or LSFH), Cable identification for ease of inspection.

As built manufacturing documentation (schemes, list of materials and list of connections) update.

Test

[ALBA]

Design and manufacturing of a radio frequency cavity

(2023 - 2025)

The project included the thermal simulation, cooling design and mechanical design and manufacturing of a the test cavity is a pillbox type cavity, with two chamfered periphery areas in which the two power couplers are placed 120° apart (for transmission measurements). The objective is to carry out tests up to 160 kW continuous wave (CW) at 500 MHz.

[Yebes Observatory ]

Supply of a laboratory cryostat

(2021 - 2021)

The purpose of the contract is to supply a laboratory cryostat for conducting tests and measurements that allows the characterization of electronic components at cryogenic temperatures before being integrated into cryogenic receptors of greater complexity.

Minimum external dimensions of the dewar without the cover: 340 mm width x 340 mm depth x 115 mm high. The thickness of the bottom of the dewar will be 20 mm and that of its side walls will be 22 mm.

Each of the four lateral faces of the dewar will have three through windows, 50 mm in diameter. Around each window, the corresponding grooves for vacuum seal.

The turbomolecular pump integrated will allow to achieve Ultra High Vacuum conditions.

[ALBA]

Supply of one (1) sample cryogenic system for BL06-XAIRA Beamline at the Alba Synchrotron

(2021 - 2021)

The system object of this contract is an instrument to maintain samples for macromolecular crystallography under cryogenic conditions, by means of a continuous laminar flow of cold gas. The system needs to be compatible with the use of nitrogen and helium gases as cryogenic gas, since the end station has been designed to allow work both in a helium environment (by means of a helium chamber) and in air. Nitrogen and helium will be input to the system as gas. The range of temperatures at sample position shall cover from 80 K to 300 K, with a high temperature stability at sample position. Achieving lower temperatures (20 K or lower) would also be beneficial for operation.

[INTA]

Positioning System for Vacuum

(2021 - 2021)

The supply requested consists of a positioning system, with a high load capacity, that allows high precision movements of an instrument in its operational spatial conditions; that is, under vacuum conditions (of the order of 10-6 mbar) and low temperature. In addition to performing the aforementioned movements with great precision and accuracy (rotations of ±20° with respect to two axes), the knowledge of the final position in which the equipment remains must be known with very low total error (minimum uncertainty), resulting It is also essential that it works correctly under vacuum conditions, that it is compatible with degassing processes (bake-out) and that it is compatible with its integration in an ISO-5 clean room. The concept of the proposed system is one of the so-called GIMBAL -from here on-, that is, based on a pivoting support that allows the rotation of an object around two orthogonal axes.

[ESS BILBAO]

Detailed Design, manufacture and Supply of the Shaft Rotatory Feedtrough for the ESS Target Station at ESS-ERIC Accelerator

(2020 - 2021)

Design, manufacture of all mechanical components, integration and execution of all verifications and tests to ensure compliance with the functional requirements and specifications.

The Rotary Vacuum Union is located at the top of the target axis, connecting the target to the helium inlet and outlet pipes that are fixed and It is essential to ensure that there is no refrigerant gas leakage, for this the sealing system must incorporate a helium injection system that always guarantees that the gas contained within the system cooling of the Target Station does not leak through the Union.

The quality of the welds will be achive providing welding qualitication records (WPQR) in accordance with EN ISO 15614-1: 2018, welding procedure specifications (WPS) and welder performance qualification according to EN ISO 14732: 2013

[IAC]

Design, manufacture and supply of a test cryostat for HARMONI preoptics

(2020 - 2020)

The cryostat for the tests of the HARMONI Pre-Optics subsystem which will be part of an integral field spectrograph for the European Large Telescope (ELT) and It is an installation to test pre-optics in the infrared range of the electromagnetic spectrum thus it needs to keep cryogenic temperatures. The POTC (Pre-Optics Test Cryostat) will consists of different sub-systems all of them necessary to ensure the function of cooling the pre-optic in order to be tested. The different sub-systems will be the cryostat (130K), vacuum subsystem, cooling sub-system.

Operational vacuum: The cryostat shall provide the infrastructure to evacuate the air within the vacuum vessel to a pressure of 10-6 mbar cold and 10-5 mbar warm and the maximum allowable leak rate of the cryostat is less than 1 x 10-9 mbar l/s.

The cryostat is fitted with an overpressure release valve which shall limit the internal pressure to ≤ 1.2 bars.

[ILL]

Detailed study, manufacturing and assembly of the ROC and Detector Support for the Instrument XTREM

(2019 - 2019)

XtremeD will be a powder diffractometer with single crystal capabilities dedicated to high magnetic field and high pressure sample environments, placed at the thermal neutron guide H24 in the guidehall ILL 7 of the Institute Laue Langevin. The ROC and detector support is composed by a support frame that slide on the marble floor with air pads, a motorized roller drive, an arm connection to the sample table and a tilt and XYZ alignements system for each of the two elements

[ILL]

Detailed Study, Manufacturing, Procurement, Assembly and Test of the Sample Table Stack for the instrument XTREMED

(2019 - 2019)

XtremeD will be a powder diffractometer with single crystal capabilities dedicated to high magnetic field and high pressure sample environments, placed at the thermal neutron guide H24 in the guidehall ILL 7 of the Institute Laue Langevin. The sample table stack is composed by a positioning system allowing to adjust the sample to the incoming neutron beam. It is led by the sample table arm. The sample table positioning system consists of an air pads module to slide on the floor, a motorized roller drive to move on the floor the sample table, a translation module, a free rotating module, a Z translation table, a rotary table, a XY translation module, a double goniometer table for angular adjusting of the sample, from the free rotating module, a connection and an arm to the ROC and detector support.

[F4E]

Supply of Vacuum Flanges for the BPM Feedthroughs on the IFMIF/EVEDA Cryomodule

(2019 - 2019)

Supply of eight radio-frequency feed-through flanges for the collection of radio-frequency signals from the eight position monitors inside the IFMIF / EVEDA Cryomodule. These flanges, which act as a transition between the exterior of the module and the interior of the SRF Linac,. The flange design is optimized for phase stability,low thermal losses, radiation resistance and connection reliability and the flanges will operate as an insulator between the insulation vacuum of the (10-3 Pa) cryostat and the atmosphere. The degassing ratio of the flanges with their connectors must be less than 1*10-7 Pa· m³·s⁻¹ per cable after 100 h under vacuum. The vacuum leak rate must be less than 2*10-11 Pa· m³·s.

[ESS BILBAO]

Detailed Design and Supply of the Waveguide Components for the RF Distribution Chains for the RFQ and DTL of the ESS-ERIC Accelerator (Lund, Sweden). Lot 2: Flexible waveguide sections

(2019 - 2020)

These components will be in waveguide WR2300 high Total (FH, English "Full-Height") or WR2300 half height (HH, English "Half-Height") for the 6 chains of the Radio Distribution System Frequency (RFDS) of the RFQ and the DTL of the ESS Accelerator. For all components, the working frequency is 352.21 MHz and a maximum pulsed peak power of 3000 kW or 1500 kW. The pulse width is 3.5 ms and the pulse repetition rate is 14 Hz (that is, a 4.9% duty cycle).

[ESS BILBAO]

Detailed Design and Supply of the Waveguide Components for the RF Distribution Chains for the RFQ and DTL of the ESS-ERIC Accelerator (Lund, Sweden). Lot 3: “Special” waveguide sections

(2019 - 2020)

The components included are Phase Shifters, Shutter Switchs, Tappers, 45° Air Adapters, Straight Adapters, Direct Directional Couplers, Magic T’s, etc. For all components, the working frequency is 352.21 MHz and a maximum pulsed peak power of 3000 kW or 1500 kW. The pulse width is 3.5 ms and the pulse repetition rate is 14 Hz (that is, a 4.9% duty cycle).

[ILL]

Study, Fabrication and Assembly of a Radial Oscillating Collimator (ROC) for the Instrument XTREMED

(2018 - 2019)

The ROC is a device placed in the scattered neutron beam between the sample and the detector. It consists on an array of absorbent blades periodically spaced, which constrain the angular view of each point at the surface of detection. The blades are made of a polymeric material (PETP) coated with several layers of a neutron absorbent substance (e.g. Gd-Oxide). All those blades are under vertical stress, the aim of this is to maintain them straight and parallel among them. These blades are hold in a stiff frame screwed on a plate (trolley). The frame made of non magnetic alloy (aluminium alloy) is surrounding the blades on the sides and on the top and bottom. No pillar or stiffener is admitted in the path of the neutron beam.

Moreover, those blades have to swing over certain angular amplitude delta2theta which has to be a multiple of the periodicity of the ROC. The velocity of the swing must be constant and reproducible.

[ALBA]

Machining and verification of different vacuum and UHV mechanical pieces

(2018 - 2019)

Periodical orders for the machining, verification and vacuum test for mechanical spare parts for the different instruments.

[ESS BILBAO]

Detailed design, Technical Support and Manufacture of Proton Beam Window Seal Mock-Up

(2017 - 2018)

The Proton Beam Window (PBW), is a component allocated in the path of the beam, and separates two atmospheres at different pressure levels. On one side of the PBW is the throttle atmosphere, with high to ultra-high vacuum levels; and on the other side, the white atmosphere, which would have a medium vacuum level. The PBW, which consists of two 1 mm thick plates, is crossed by the proton beam, which will deposit approximately 5kW in its volume. This power is evacuated by a 2mm water channel, cooled by a flow of 0.3kg water that circulates inside these plates. To ensure the required vacuum conditions on both the throttle and the blank side, the PBW must be properly sealed on both sides, ensuring that the atmospheres on each side are maintained, with a leakage rate of less than 2 - 3 · 10-5 mbars –l/a. The sealing device will be placed on both sides of the window, and fixed so that it descends attached to it. Once in position, the seal must be activated remotely.

Relevant R&D projects

[YEBES OBSERVATORY]

Supply of filtering, switching, distribution and baseband conversion modules (4-18 Ghz) for the ASTROREC receiver of the 40M radio telescope

(2022 - 2023)

The project included the design and manufacturing of the technical solution adopted to comply the supply of pre-amplification, distribution and frequency conversion to baseband, necessary for the receiver YNART (4-18 GHz) for the Yebes observatory.

INDRA - RF-ALQ500 modules upgrade. Re-design, manufacture and qualification of different filter banks range 2-18 Ghz

(2019)

INDRA - Design, manufacture, assembly and qualification of a High Power Calibrator Module System (0,5-18 Ghz)

(2019)

[SODERCAN]

Design and manufacture of a reconfigurable, ecological and extreme performance cryogenic manipulator

(2019 - 2019)

The purpose of the contract is to supply a laboratory cryostat for conducting tests and measurements that allows the characterization of electronic components at cryogenic temperatures before being integrated into cryogenic receptors of greater complexity.

Minimum external dimensions of the dewar without the cover: 340 mm width x 340 mm depth x 115 mm high. The thickness of the bottom of the dewar will be 20 mm and that of its side walls will be 22 mm.

The dewar (450 mm x 150 mm) has 12 windows integrated for the manipulation of the samples and its corresponding grooves for vacuum seal.

The turbomolecular pump integrated will allow to achieve Ultra High Vacuum conditions.

INDRA - Design, manufacture, assembly and qualification of intermediate frequency signal conditioner and RF signal conditioners

(2018)

CAF - RF Design and test for signalling and security balises as part of an automatic train protection (ATP) system

(2018 - 2018)